Veneer production

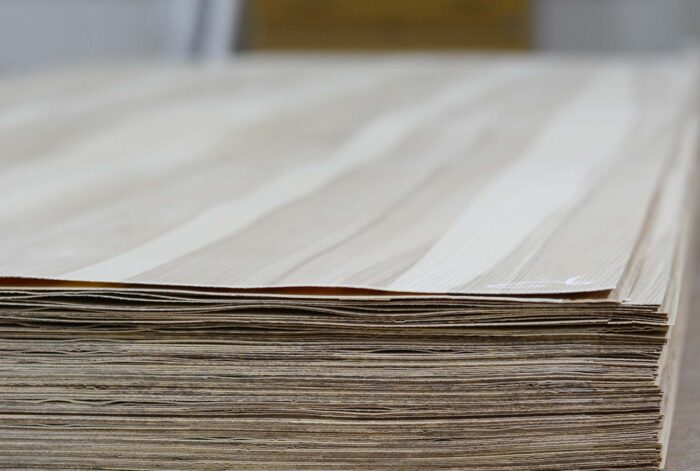

Veneers are sheets of wood in thickness 0,4 mm to 5 mm. Veneers are cut from the log by sawing, slicing or peeling. The sheets are then glued onto a board, such as particleboard, MDF board or plywood.

With our own log buyers the round logs are inspected in different places around the world. In this way we can control the whole process from the harvest of the logs until the veneer arrives in our warehouse in Vaggeryd.

When the round logs arrives to the veneer slicing company, they are prepared to optimize both yield and quality.

The veneer slicing is always done with the most modern veneer production technique in the world, this to ensure our customers high demands.

Inspection

Round logs

Steamed Veneer

Slicing techniques

Veneers are sheets of wood in thickness 0,4 to 5 mm

Dyed veneer with endless possibilites

The veneers are manufactured through a four-stage process, composed of bleaching, dyeing, drying and pressing. The sheets are lowered in the dye so that it fully penetrates the veneer, resulting in a uniform color and an enhanced natural grain. Dyed veneers are widely used in furniture and interior design projects, as well as in the automotive and marine industries.

Spliced Veneer

Veneer jointing

Slicing techniques

The log is cut in half, and the half log or flitch is then sliced straight across, parallel to a line through the center of the log and tangential to the growth rings. This generally produces a veneer with a central area of strong figurative grain and a more linear effect at each edge.

Quarter Cut

Straight-grained, cut at right angles to the growth rings.

The log is cut in quarters, and each quarter flitch is then straight sliced, approximately at right angles to the growth rings. This generally produces a veneer with a relatively uniform linear vertical grain.

Splicing techniques

Veneer sheets produced from a single log are placed in a mirror image (as an open book).

Slip matching

Veneer sheets produced from a single log in a slip after each

Veneers in which consecutive veneer sheets are taken from the same flitch and placed next to each other without turning them.

Random mixed veneer sheets

Mack Fanér

Frideborgsvägen 13

567 30 Vaggeryd

Sweden

Phone

+46 (0) 393-120 20